G'day guys!

First off, thank you & Happy New Year! We want to say thank you to every single one of you for being a part of this journey with FlyingIron; for flying our planes, sharing your thoughts & feedback in our Discord & social media channels and for sticking by us through 2022 and beyond!

2022 has been a big year for us & 2023 is set to be even more exciting!

In this report we'll be updating you on what we've been working throughout the year, as well as what's set to come in both MSFS & DCS World. Let's get started!

Image Courtesy of Lodkins

General News

This year we were extremely excited to bring in a new member to the team, bringing up our team numbers to 4 full-time members! We are *extremely* selective with who we bring into the team (as evident by us only bringing in 2 new members in our 4 years of existence), so this was a major breakthrough for us. Iakov joined our team as a full-time member in 2022; an extremely talented 3D artist with a passion for all things aviation, Iakov has worked with large game studios in the past and has created several incredible aircraft models which have been used by various teams in MSFS and other games. Iakov has taken on the role of 3D modelling, providing an unmatched level of detail in all his work.

Our team of test pilots & beta testers has grown in 2022, including several real-world pilots with extensive experience flying warbirds. Our test team has been invaluable all throughout 2022, so we'd like to give them a big shout-out here and say thank you for your continued efforts and commitment to detail!

FlyingIron has featured in several printed magazines around the world in 2022, and we've also been in talks with museums and air exhibits around the world to incorporate FlyingIron simulations into simpit attractions. Our Spitfire has even attracted the attention of the RAF! More news on that to come later down the line.

2022 even saw FlyingIron make a small feature in the academic world of CFD study! We were very excited to be a part of a presentation at NASA's OpenVSP workshop as a collaboration with Research in Flight. As part of our work with Research in Flight we created some simple software that can convert CFD models between OpenVSP and Flightstream, creating a more streamlined pathway for FlightSim developers & academics to test prototype models in a CFD environment.

It's been an exciting year and we can't wait to continue that in 2023!

Image courtesy of mr blox

Microsoft Flight Simulator

2022 saw the release of our F6F Hellcat for Microsoft Flight Simulator, which has been received very positively. Thank you for your support! Although we only saw one aircraft release this year, we've also seen numerous major updates to the Spitfire as well as the P-38 Lightning. These updates have included major improvements in almost all areas and are designed to bring all of our releases up to the same standard of our most recent releases, aiming to ensure a consistently high quality across all of our modules. While it does mean that we aren't able to release as many modules as we otherwise could in a year, we believe the trade-off of having consistently improving aircraft modules is worth the time investment.

Without further ado, let's look at some of the key development updates that we've been working on & incorporated into our modules in 2022.

Flight & Systems Modelling

Throughout 2022 much work was spent on improving the overall flight modelling, engine modelling & systems modelling across all of our aircraft. Some of these changes involved incorporating new MSFS features, adjusting & accounting for updates and physic changes in the sim and other general maintenance work. There was, however, a significant portion of time devoted to expanding upon our current flight & systems modelling to add a new layer of detail & realism.

One part of the improvements in flight modelling is the incorporation of MSFS's new CFD modelling (Computational Fluid Dynamics). This has been a significant upgrade to the overall fidelity of flight physics in the sim, however only when correctly implemented by each developer. The enhanced CFD model creates a dynamic & real-time simulation of air particles flowing around the aircraft, which in turn allows for the simulation of the forces these particles enact on the aircraft. This type of modelling is supplementary to our existing flight models, intended to aid & enhance by providing a more detailed simulation of flight elements that cannot be easily captured via look-up tables and differential equations, such a propwash physics or flow interaction with peripheral elements such as the landing gear.

To supplement this, we've also been gathering aerodynamics data that is not typically available for warbirds by utilizing our in-house CFD utility software to quickly gather and verify aerodynamic coefficients. We are then using the results from our CFD analysis directly in MSFS. For more information about this, please see the A7 section of this report, in the CFD subsection.

On top of this, much work has gone into further detailing core aircraft systems and engine modelling. We have been developing a much more detailed landing gear system, featuring multiple failure points, collapsible gear and more. We have worked on immersion factors such as basic damage modelling, including bent props from ground strikes. Following on from our earlier work last year, more time has been spent expanding upon & tweaking engine thermodynamics and engine management to be as realistic as possible. As you may already know, all of our engine thermodynamic models are custom coded in-house and deliver a simulation that is far deeper than the simple heat modelling offered in MSFS, and we have expanded them significantly in 2022 with feedback from our real-world warbird pilots.

Custom Ground Physics & Handling Model

One of our biggest undertakings in 2022 has been the development of a fully-custom, in-house ground handling model for our aircraft. This has been a major priority as we of course specialize in prop-driven warbirds, with a large number of those being taildraggers. Initially we used the basic MSFS ground handling model, optimizing it as best we could to try and suit our aircraft. This was however severely limited by the lack of free-castor wheel physics in MSFS.

Rather than waiting any longer, we have taken it into our own hands and developed a free-castor wheel physics model in-house, to be used across all of our aircraft modules. This system took quite some time to develop and involved some very intensive physics coding to try & recreate the underlying forces that influence ground handling. After many months of development & testing with our test team, we have come up with a model that we are very proud of and are currently in the process of integrating the new model with all of our aircraft. Our ground handling model provides a much more realistic simulation of a free-castoring wheel and the unique quirks that influence its handling, including propwash & engine power, differential braking, ambient wind conditions, airspeed and much more.

To summarize the model: true free-castoring wheel physics, no more basic rudder-linked tailwheels!

Image Courtesy of JWinnicker

Sound Design

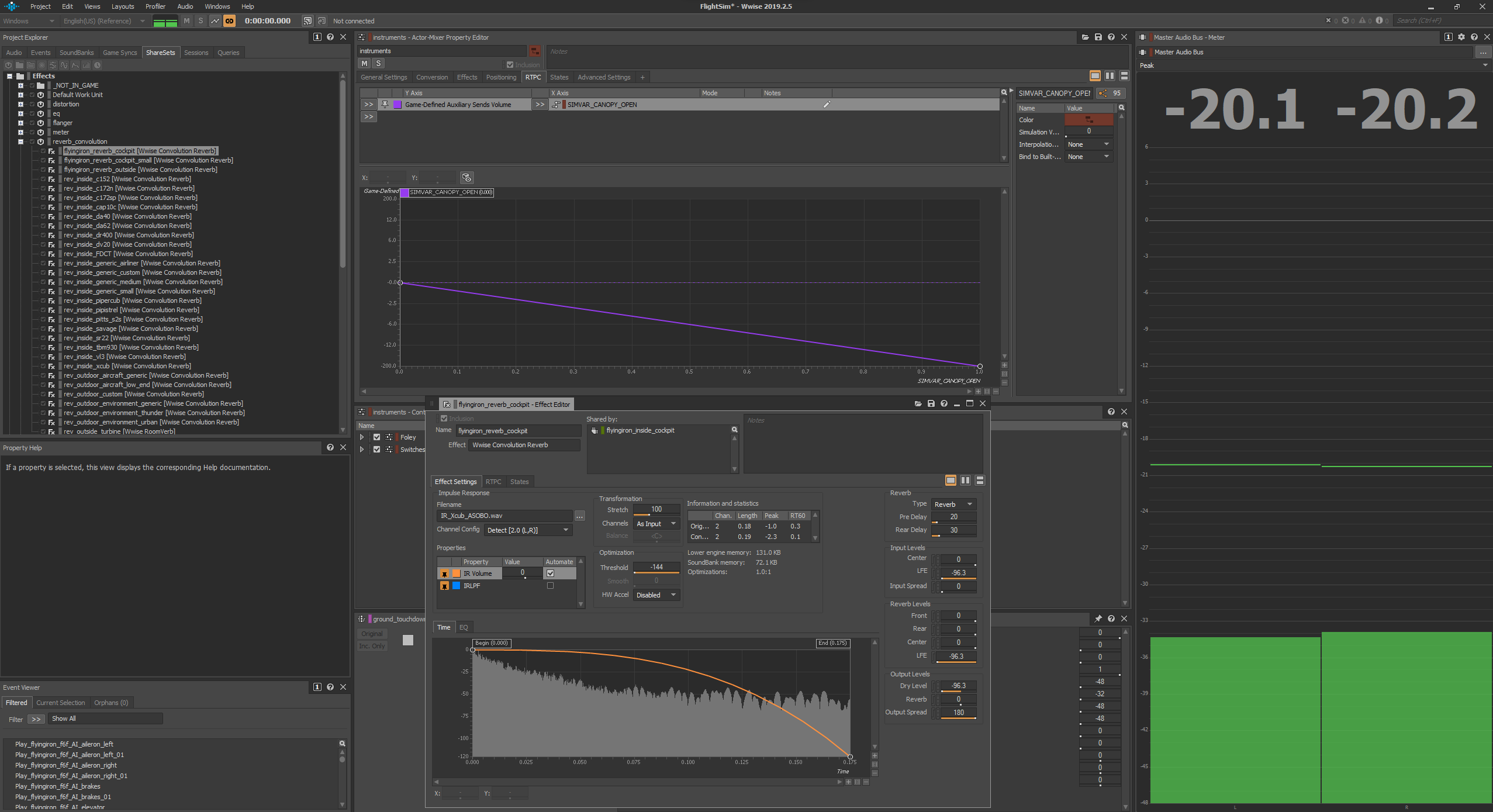

This year, and especially these last 3-4 months, we've been hard at work completely remaking the soundscapes we have created for MSFS. Whilst many samples remain the same, an enormous amount of work has been going on behind the scenes in order to greatly enhance the fidelity, detail and dynamic nature of sound in FlyingIron modules.

This has been achieved via a complete overhaul and remake of our base Wwise sound design template, using the Spitfire as our first test model to have the new soundscape applied to. Almost everything has been remade from the ground up, using much more efficient techniques with a much deeper level of interconnection between sound & sim. This sounds alittle vague, so let's look at some examples of how the soundscape has improved in our upcoming Spitfire MkIX update.

Mixing & Routing

We've remade our Wwise template to use a significantly better audio routing structure, which results in a more balanced soundscape, more audible interactions between sounds and a better integration with UI slider controls to give the user more flexibility to adjust the soundscape.

Reverb Enhancements

We have developed a brand-new, in-house reverberation system to be used across all of our modules. This includes a dynamic & highly realistic cockpit reverb simulation, which is accurately affected by cockpit insulation properties, such as whether or not the canopy is closed (or in the P-38, how many doors/windows are open). A closed & sealed cockpit will have a much greater reverb effect, accurately simulating the echo & bouncing of soundwaves through the cockpit, compared to an open cockpit where the soundwaves can escape.

Complementing this is our new exterior reverberation system, designed to simulate the large reverb effects that you hear when you listen to an aircraft passing by. We have developed multiple reverberation systems for exterior sounds, including generic open reverbs of multiple sizes, as well as a highly modulated reverb & delay system that we have created to better mimic the physics of soundwaves travelling outdoors.

Both reverberation systems make full use of Impulse Response (IR) modelling to achieve the most realistic effect possible. IR modelling is a fascinating sound design technique, where a special recording is taken from inside a space or area of interest and the recording is then used to produce an IR file that captures the exact sound qualities of that space. This IR file is then used by sound designers (such as us) to apply those unique sound qualities to other sounds, essentially making them sound as if they were recorded in the same space. Here at FlyingIron we are proud to say we are use IR modelling in all of our reverberation systems, with some captured from inside various aircraft and others captured in generic outdoor spaces.

Custom Attenuation Modelling

As part of the new soundscape we have completely replaced & remade the attenuation sets in Wwise provided by Asobo. These attenuation sets control the parameters of sounds in world space, affecting things such as volume attenuation over distance, high & low pass filtering, 3D positioning and panning properties. We have developed a set of unique FlyingIron attenuation models to be used in all our aircraft sounds, including specific models for inside the cockpit, generic outsides, propeller models as well as engine models.

Our new attenuation models have been designed to be significantly more realistic than the generic models - they not only capture the acoustics of the various aircraft aspects, but also the influence of physics on soundwaves. For example, the exterior attenuation models are influenced by airspeed: at low speeds, the engine can be heard all around the aircraft, but most strongly at the exhausts. At increasingly higher speeds approaching Mach 1, the soundwaves & attenuation cones will be 'flattened', with sounds becoming far less audible in-front of the aircraft due to the differences in speed between sound & light.

Overhauled Ground & Wind Sounds...

Ground sounds have been significantly improved to account for a much greater variety of ground surface types, as well as greatly enhance the level of dynamic modulation & filtering techniques used in the sounds with the goal of increasing pilot feedback & immersion. Furthermore all wind sounds have been remade & remodelling with new modulation factors, aimed at also increasing immersion and being more responsive to airframe & weather conditions. Some examples from both include:

- Crash, Splash, Impact & airframe scrape sounds integrated

- Improved ground roll modulation, overhauled touchdown sounds & integrated vertical velocity & speed modulations

- Replaced all wind sounds, updated airframe wind to be affected by ambient winds, Angle of attack, Altitude above ground and many more factors.

- Propwash overhauled & integrated in a more realistic way with smoother transitions between propwash & airspeed winds

- Added wind sounds for flaps, gear & AoA for better feedback to the pilot

...And Much more!

There are far too many improvements for me to explain in detail, so here's a dot point summary of some of the other changes made!

- Overhauled Flyby sound processing

- Improved canopy insulation modelling

- Wing Loading & G-force stress sounds added

- New engine-start & shutdown sequences with greater complexity & realism

- Overhauled prop sounds

- Additional foley sounds added: cockpit controls, levers, flight control surfaces (ailerons, rudder, elevator)

- Overhauled fuel pump sounds & modulation

- Improved engine sounds via traditional music design techniques such as parallel compression - used to dynamically 'fatten up' the engine sounds in response to RPM & MP changes

- Gyro/electrical sounds added

- Improved sound debugging workflow to enhance work efficiency

Modular Development Flow

One of our priorities this year as we've worked through various updates, developing new systems & codebases, has been to make each new feature completely modular and transferrable between modules. We are achieving this through the creation of special FlyingIron template models, used in the XML code, which provides us with all of the primary functionality of our new system designs whilst still allowing us to tweak things to suit each airframe correctly.

Whilst there is still significant work to be done tweaking & matching each template to function correctly & accurately for each airframe, having a modular system like this in-place allows us to develop a significantly deeper & more realistic codebase for each airframe in a much shorter timeframe. This in-turn allows us to continue developing new, better & deeper systems that are continually improving and being expanded upon in each update. Furthermore, it gives us the ability to continually update & improve our previously released modules, creating a consistently high standard across all FlyingIron modules.

So far this year we have released several updates for all of our MSFS modules for exactly this reason, with many more to come!

Enhanced Electrical System Modelling

Another priority for the past 4-5 months this year has been developing an all-new electrical system to be used in our MSFS modules. We wanted the system to be significantly more detailed than the standard MSFS electrical modelling and modular as discussed above, so that it can be shared across all our modules and tweaked to suit the specific airframe.

We've made excellent progress on this, going as far as modelling functional circuit breakers. Building upon the basic MSFS system of a battery & generator, our system will include accurate bus & circuit modelling, emergency power circuits (where applicable), correct modelling of individual circuit power demands and more. The end result will be an accurate model of an airframe electrical system and will require correct cockpit management by pilots to ensure it stays operating within designated limits. It also creates the possibility of simulating failures via the CBs.

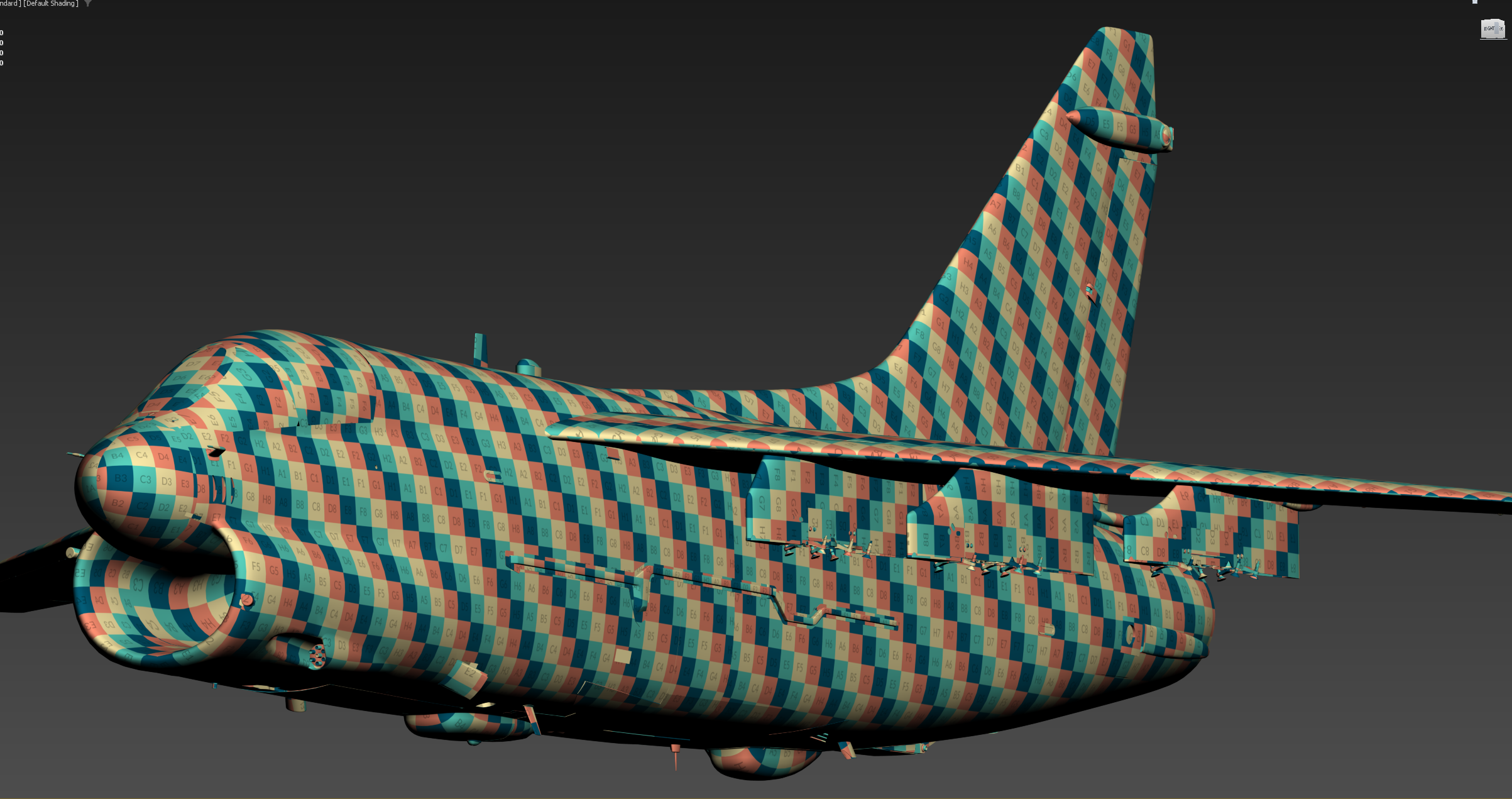

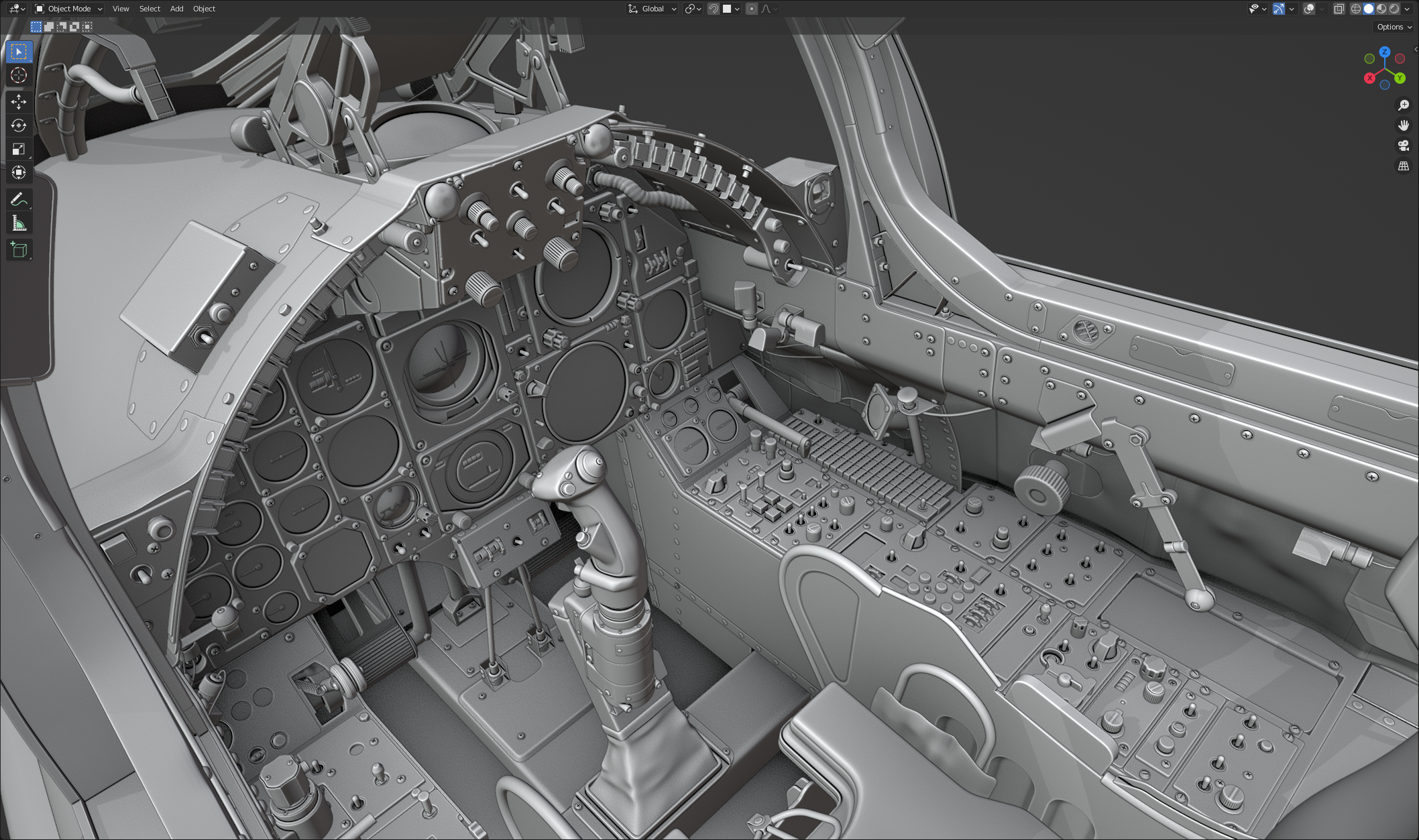

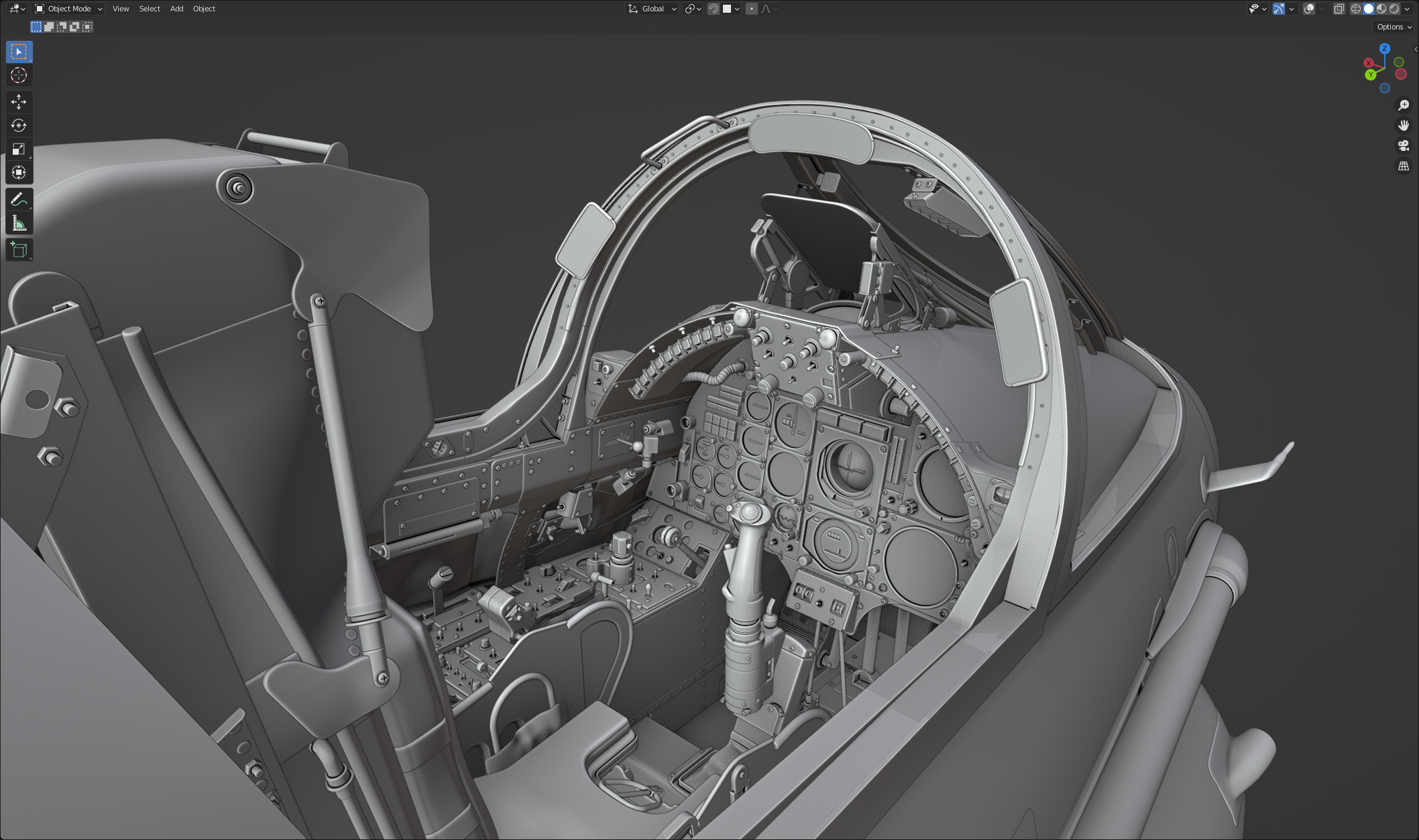

Artwork

While there isn't much to say here, there is plenty to show! 2022 saw Alex & Iakov working on brand new models for our upcoming aircraft and in the process experimenting with and developing new techniques to improve both the fidelity of the art as well as the optimization and performance. We've also been working to develop new art methods to increase immersion, such as the simulation of a bent prop after a prop-strike, visual FX in the form of engine smoke/fire/exhaust flashes as well as experimenting with malfunction and damage simulation. Visual immersion has been a focus of 2022, with work now being done on minute details, such as the flickering of instrument lights during start-up or the vibration of needles & cockpit instruments.

Image courtesy of BavariaSmoke99

Image Courtesy of JobuRum

A7 Corsair II for DCS World

Artwork

The Corsair has had a tumultuous journey! 2022 saw the completion of our complete remake of the A7 3D model, which took a significant amount of time. With the aid of Iakov, our new artist, both the external and internal models of the A7 have been completely remade from scratch as we've previously discussed. The remake started work in 2021 and was completed around Q3 in 2022. The remake is significantly more detailed than our original model, with almost all elements of the aircraft accurately modelled, including maintenance areas.

Having such a detailed model delivered by Iakov meant that lots of work was required in terms of optimizing the model to extract the maximum possible performance, without compromising much detail. This is still ongoing, however most of the exterior has now been optimized, as well as large chunks of the cockpit. Work is ongoing to optimize the remainder of the cockpit so it can then be textured.

Work has begun on UV mapping the exterior model and to that end we have created a dedicated Paint-Kit team, who are providing value feedback during the UV mapping process to ensure that our paint-kit is as easy to use as possible for livery artists.

Work is also well underway in animating the cockpit & exterior as well as setting up clickable areas, which has been very helpful in allowing us to start testing more systems in-flight using proper procedures.

Flight Modelling

The A7 Flight Model has undergone extensive work this year, especially in the first half of the year, with much of that work being 'behind the scenes' so to speak. This year we've been working closely with Research in Flight, an aerospace & hydrodynamics analysis company that creates tools for aerospace engineering applications. They are the developers of Flightstream, a sophisticated numerical flow solver and one of our primary tools that we use for CFD analysis & data collection for the A7.

We have been working closely with them to enhance & improve our A7 Corsair model, to the point where we have been able to supply validation studies and case tests against the real wind-tunnel data we have gathered. The A7 model has also been used to test & assist in development of new control surface analysis techniques being integrated into Flightstream, in turn also enhancing our data collection capabilities for various control surface & damage configurations.

CFD Collaboration & NASA Presentation

As part of our collaboration, we spent some time this year developing some internal tools to aid in the collection of CFD data; not only for the A7 but also for any model we wish to analyze. One such tool that I developed personally was a utility that facilitated the conversion of an OpenVSP model into a solution-ready FlightStream model. Without going into too much detail, what this accomplished was an extremely fast & efficient method for simple OpenVSP geometry models to be analysed in great detail in FlightStream. For us, this allows us to gather CFD data in a fraction of the time required using traditional modelling techniques. Our work was shown off at the 2022 NASA OpenVSP workshop, and we have since made the tool publicly available, where it is now being used around the world in both academic & commercial design purposes. We have even been informed the utility is being used over at Boeing! It is our hope that this simple tool will make CFD modelling more accessible to all sim developers. For further reading, you can see the presentation slides that relate to the relevant Flightstream developments here.

Of course, all this only matters if it helps us to develop the A7! Although it's taken some time, these developments have been a worthy time investment. By forging a new workflow, we're able to tweak & experiment with our models in a fraction of the time to get the best results possible when testing unusual aircraft configurations. If you've worked with CFD or know alittle about it, you'll know that it is an enormously time-intensive process using conventional techniques, and almost always requires constant model tuning & tweaking to collect valid results. As we are now developing the advanced aspects of the A7 Flight Model, this has been absolutely essential when testing non-standard configurations.

For example, using our workflow we've been able to run tests and collect data on virtually every control surface interaction possible, in order to assess the relative significance of unusual interactions and determine how best to model them in-sim. Some examples include interactions between the flaps & elevator at various high Angle-of-Attack configs, forces in a spin and leading to a spin, spin recovery analysis and post-stall analysis. Furthermore, this new modelling workflow has provided us with a very efficient means to study the effects of airframe damage on flight dynamics, an aspect that is often modelled with only very simple approximations due to data limitations. Not so anymore!

Design & Development of Control Augmentation System (CAS) and Automatic Flight Control Systems (AFCS)

In terms of Flight modelling, the latter half of 2022 has been heavily focused on designing & developing the CAS for the A7 Corsair. This has been a huge undertaking and admittedly has required a large amount of time on my part devoted to studying advanced engineering control system design principles.

Although we don't have the exact equations used in the real aircraft CAS, we do fortunately have enough information on the inputs & outputs of the system to be able to reverse engineer it. This has required us to approach the situation in much the same way as the original aircraft designers, attempting to carefully craft a control system that meets the requirements of the airframe and pilots.

Although work is still ongoing, we are quite pleased with how things are shaping up and are confident that with the feedback from our SME's we will be able to fine-tune the CAS to operate almost exactly as the real system would. Flying with the CAS switched on is a completely different experience than flying with it off; the airframe is incredibly difficult to control without it. Therefore, it is absolutely critical that we get this right and we are dedicating an appropriate amount of time & resources to try and achieve this.

The CAS is only one part of the A7's AFCS, which is used not only to enhance flight stability but also for Autopilot control of the aircraft. The AFCS is being developed in tandem with the CAS and has made significant progress in 2022. The primary Autopilot modes (HDG, ALT, ATT, Airspeed) have all been developed & implemented. We are currently in the process of refining the Yaw Stab system, which stabilizes and corrects for aircraft slip and assists in turn coordination.

CAS & AFCS naturally have a strong interconnection with the control surfaces and thus required a complete rewrite of all of our control surface models. This was completed in 2022 and are controls are now working in harmony with the AFCS, respecting defined authority limits and behaviours. As a pilot you will need to be aware of & respect these limits to ensure that you are working with, and not against, the AFCS.

The A7 Corsair is not a simple airframe to fly; it has extensive quirks that need to be understood and mastered for the aircraft to be flown effectively. The AFCS is a quintessential part of this; understanding & mastering it will be a key component of flying the A7 well.

Other FM Developments

On top of everything discussed above, this year we have been working to refine our mathematical classes & methods implemented in our codebase. Focusing on optimization, we have been spending time implementing new methods of data processing that require less computational resources to achieve the same result. An example of this is interpolation and look-up table (LUT) modelling, which is the foundation of data processing in a simulator and one of the primary methods used to implement CFD & aerodynamics data. These calculations happen thousands of times every second and have thus been a big priority for us in terms of code optimization.

As discussed in the CFD section, we have developed a new workflow that has allowed us to quickly and efficiently analyze aircraft damage scenarios and the impact of damage on Flight dynamics. While still in-progress, we have been very pleased with the data we've been able to collect and are currently busy expanding the Flight Model to include damage modelling.

Sound Design

Although still only in the very early stages of development, work has begun on sound design for Corsair! Thanks to the collaboration from some amazing people in the community, we've been able to organise the recording of a real A7 during a maintenance engine run. This is of course an extremely rare opportunity, and we are so grateful to the good people at Tulsa Tech University for making this possible!

Thanks to some collaborative efforts from 'Armorine' in our community discord (who has also been invaluable in helping us to secure certain documents. Thank you Armorine!), we were able to organise a professional field recording of the A7. The recording was carried out by Tulsa Tech's team of sound engineers & sound engineering students, with the entire engine run captured from various positions by professional grade equipment. The team even went so far as to produce an excellent master of the samples for us! In total we were given an amazing 29 high-quality aircraft samples from various mic positions, as well as 4 completed mixdown tracks.

We will be applying many of the lessons that we've learned from sound design in Wwise/MSFS to our A7 sound design work; for more detailed information I encourage you to read through the sound design subsection of the MSFS report above.

Below you can see some shots from the recording process

Tulsa Tech sound engineering team, responsible for the excellent recordings provided.

Images provided by Tulsa Tech & Armorine

System & Weapons Development

Alongside all of this, work has continued throughout the year to develop and flesh out the cockpit systems of the Corsair. Once again, we owe our thanks to 'Armorine' for assisting in helping us to acquire some missing documentation. Unfortunately, due to the nature of systems development, we don't have a wealth of flashy screenshots to show here, but I will do my best to explain the various systems under development and the state they are in.

One of the biggest priorities this year has been developing the codebase & logic underlying the A7's targeting and weapon delivery systems. To this end, lots of time has been spent refining and further developing the armament control systems: developing correct pylon release cues & logic, release inhibition conditions, developing calculations for interval drops and developing the core logic that underpins the sophisticated weapons systems of the A7. The culmination of this has been the development and integration of CCIP & CCRP weapon release modes; both of which draw heavily from various sensors and targeting systems in the aircraft before making real-time calculations to determine an impact point. We are pleased to say our A7 can now accurately release unguided weapons on target, using both CCIP & CCRP methods that are unique to different weapon types. Work is ongoing to further develop both weapon release modes to include inhibition cues as well as to develop the navigational modes of weapon release, such as Bomb on Coordinates (BOC) and offset bombing modes.

Navigation systems also received some development time in 2022, with the INS and tactical computer systems currently being expanded upon and developed. We have developed the aircrafts waypoint system, including storage, recall and editing of flight plan waypoints. We've also made progress integrating information from the navigation systems into other aircraft avionics; most importantly the HUD and PMDS. 2023 will see the detailing & expansion of the INS system; expanding on current modelling of the Inertial Measurement Unit (IMS) and the development of the Doppler Radar, both of which feed information to the INS. We will also be working to implement mark-points, target points and other in-flight navigational systems. As a pilot flying the A7 will require careful monitoring and management via positional updates and pilot corrections; the A7 requires navigational updates to correct for INS drift, in a similar fashion to the Viggen.

As we've shown throughout the year, 2022 has seen the development of most of the A7's key avionic systems in various states of completion. The Projected Map Display (PMDS) is integrated and functioning, with current work focused on integrating navigational data from the Tactical Computer, as well as integrating some of the lesser used functionalities. The RWR has been on the backburner for some time due to some limitations in documentation, however we have now obtained the necessary documents and work is now ongoing in developing the RWR fully! The aircrafts multiple radio systems are also well in development, with the primary functionality of all radios already implemented and work ongoing to implement cockpit controls, presets and other functions. The A7 Radar systems are also well in-development as we've previously showcased, with current work focused on radar targeting functionalities as well as navigational cues.

As well as all the above, our current codebase is being constantly refined, expanded upon and rewritten in order to be more realistic with its flow of information. To elaborate, we are aiming to mimic the flow of data as it occurs in the real A7 avionic systems, with many avionics being dependent on other systems and prone to certain failures and accuracy limitations. For example, the tactical computer relies upon information from the Air Data Computer (ADC) as well as IMS systems in order to complete navigational and targeting calculations; any inaccuracies in data supplied from either the ADC or IMS will result in flow on errors and inaccuracies further down the avionics chain. In practical terms, this means that simple things like damage or icing to your pitot tubes can result in inaccurate data being supplied to the ADC and thus the Tactical Computer, creating targeting & instrumentation inaccuracies. We want each system to be interacting with each other as organically and realistically as possible, allowing for the accurate simulation of failures, errors and inaccuracies as they can occur throughout the aircraft.

To summarise the state of systems development in the A7 Corsair: most if not all systems have been developed and integrated to at least a basic extent, with work now being focused on expanding and developing the advanced functions of each system as well as the interconnections between each system. This will happen in-tandem with the art, as more & more cockpit controls and displays become available and ready to be tied to code work; we anticipate this will be ongoing for much of 2023.

What's next?

We've previously discussed our 4-phase development roadmap for the A7, which roughly translates to the following 4 phases:

- SFM Based model

- Basic EFM & flight systems

- Advanced EFM & advanced flight/weapon/avionic systems

- SME testing & tuning + damage modelling

We are currently approaching the tail-end of phase 3, which as expected has been the longest development phase by quite a margin. Our goal is to complete phase 3 and move into phase 4 of development at some point in 2023. We know it's been a long wait and it seems to still be forever away, but we want to say thank you for your patience and hopefully this report can give you some insight into what's been happening behind the scenes.

2023 & Beyond

BF-109G6 for MSFS

FW190 for MSFS

Last but certainly not least, 2023 will see us commence work on our first 4-engined aircraft for MSFS...

Stay tuned in 2023 for the announcement!

Happy New Year & Thank you for reading!

Sincerely,

Dan, Alex, Raimond & Iakov

FlyingIron Simulations

Follow Us

I’m really looking forward to your new creations for 2023, particularly the bf109 and FW190. I’ve clocked up about 500 hours in the Spitfire now, and still absolutely loving it! Thank you!

Thank you for all of your hard work. I am really looking forward to your A-7 Corsair II for DCS and pray that further DCS modules from FlyingIron Simulations will follow (hoping you can convert your MSFS F-117 to a DCS standard)

Happy New Year and all the best for 2023

Thanks for the in-depth update on your plans for the future, it sounds truly exciting. So far I have the Hellcat and Spit and love them to death. It’s great that you are going to continue to tweak them. I’ll certainly be buying more of your library, certainly the 109 and 190.

I do have a small suggestion. You say there isn’t much to discuss as far as artwork, but I’ll have to disagree a bit. When screen shots of the Hellcat came out, there were obvious errors in the markings that weren’t trivial, and were pointed out backed up by period photos. You were receptive which is awesome. I would encourage you guys to take as much care with markings and camo as you do with the rest of it, as that will be one of the first things noticed in preview shots.

Hi, just absolutely love your work (I own the Spitfire and the P38). Your update was very interesting to read, just blows my mind the deapht you go on your research! Could the 4 engine plane be a B17…?

Your team does amazing work!

I am enjoying your Spitfire, P38 and Wildcat and can’t wait for the BF109.

You do such great work with sound designs and looking forward to hearing the Messerschmitt.

Now if Microsoft will just release fly-by mode!!!

Leave a comment